Inhaltsverzeichnis

Spannlager

- Lagerausführung

- Belastbarkeit

- Ausgleich von Winkelfehlern

- Schmierung

- Abdichtung

- Drehzahlen

- Geräusch

- Temperaturbereich

- Käfige

- Lagerluft

- Abmessungen, Toleranzen

- Nachsetzzeichen

- Aufbau der Lagerbezeichnung

- Dimensionierung

- Mindestbelastung

- Gestaltung der Lagerung

- Ein- und Ausbau

- Rechtshinweis zur Datenaktualität

- Weiterführende Informationen

Spannlager

Spannlager sind einbaufertige Maschinenelemente. In Kombination mit gezogenen Wellen sind sie besonders montagefreundlich und zur Gestaltung wirtschaftlicher Lagerungen geeignet. Sie eignen sich gut, wenn überwiegend radiale Belastungen aufgenommen werden sollen.

Spannlager mit verbreitertem Innenring haben eine geringere Verkippung zur Folge und laufen dadurch ruhiger.

Spannlager mit sphärischem Außenring eignen sich gut, wenn:

- statische Winkelfehler der Welle ausgeglichen werden müssen, die durch Montageungenauigkeit und Toleranzen in der Anschlusskonstruktion verursacht werden ➤ Abschnitt

- bei Umgebungsbedingungen wie Staub, Schmutz, Feuchtigkeit, Steinschlag und Stößen sehr gute Dichtungen notwendig sind ➤ Abschnitt.

Spannlager mit zylindrischem Außenring eignen sich gut, wenn:

- bereits eine zylindrische Gehäusebohrung vorhanden ist

- der Außenring der Lager durch montagefreundliche Sprengringe fixiert werden soll.

Spannlager mit profilierter Bohrung eignen sich gut, wenn:

- über Wellen sehr hohe Momente übertragen werden müssen.

Spannlager mit Gummidämmring eignen sich gut, wenn:

- Schwingungen und Stöße aufgenommen werden sollen

- Laufgeräusche gedämpft werden müssen.

|

Ausgleich statischer Winkelfehler, verfügbare Dichtungen mit unterschiedlich starken Dichtwirkungen η = Dichtwirkung |

|

Lagerausführung

Ausführungsvarianten

Die Spannlager haben eine sphärische oder zylindrische Mantelfläche. Sie werden vorwiegend mit einem Exzenterspannring oder mit Gewindestiften auf der Welle befestigt.

Die Abdichtung der Lager erfolgt mit einer Reihe zur Verfügung stehender Standarddichtungen, die jeweils auf unterschiedliche Anwendungsbedingungen angepasst sind.

Spannlager gibt es in folgenden Ausführungen:

- Standardlager nach ISO ➤ Link

- Korrosionsbeständige Lager in VA-Ausführung oder Corrotect-beschichtet nach ISO ➤ Link

- Black Series mit Durotect BS-Beschichtung nach JIS B 1558 ➤ Link.

Darüber hinaus stehen Spannlager auf Anfrage in vielen weiteren Ausführungen und Größen sowie für spezielle Anwendungen zur Verfügung.

Zahlreiche Baugrößen werden in X‑life-Premiumqualität geliefert. Diese Produkte sind in den Produkttabellen gekennzeichnet.

Spannlager in X‑life-Premiumqualität haben beispielsweise eine niedrigere Rauheit Ra und eine bessere Formgenauigkeit der Laufbahnen als vergleichbare Ausführungen ohne X‑life. Dadurch ist zum Beispiel bei gleicher Dimensionierung die Tragfähigkeit und Lebensdauer dieser Lager höher. Bei bestimmten Anwendungen kann so gegebenenfalls die Lagerung kleiner ausgelegt werden.

Bei Spannlagern in X‑life-Premiumqualität wurde zudem der Exzenterspannring konstruktiv verbessert und die Schmierstoffmenge und ‑verteilung optimiert. Gehäuse ASE haben zusätzliche Querstreben an der Unterseite. Für extreme Anforderungen wurde der Käfig- und Dichtungswerkstoff bei den Hoch- und Tieftemperaturausführungen (Nachsetzzeichen FA101) gegenüber früheren Versionen deutlich verbessert.

Metrische und zöllige Ausführungen

Die Spannlager sind in metrischen Abmessungen erhältlich. Einige Baureihen haben Bohrungsdurchmesser in Zoll-Abmessungen.

Standardlager nach ISO

Grundlage der Spannlager sind die Rillenkugellager-Reihen 60, 62 und 63. Die Zahlen kennzeichnen den Kugelsatz und damit auch die Tragfähigkeit des Lagers ➤ Abschnitt. Der Innenring ist ein- oder beidseitig verbreitert, die Bohrung hat bei den meisten Ausführungen eine Plustoleranz.

Spannlager sind besonders montagefreundlich und für vorzugsweise gezogene Wellen der Toleranzklassen h6 Ⓔ bis h9 Ⓔ geeignet. Für Loslager werden Wellen der Toleranzklassen h5 Ⓔ bis h7 Ⓔ empfohlen.

Sphärische Mantelfläche zum Ausgleich von Fluchtungsfehlern

Spannlager mit sphärischer Mantelfläche sind einreihige, montagefertige Baueinheiten, bestehend aus massivem Außenring, Käfigen aus Kunststoff oder Stahlblech und Dichtungen P, R, L oder T ➤ Tabelle. Lager mit beidseitig verbreitertem Innenring haben eine geringere Verkippung des Innenrings und laufen dadurch ruhiger.

In Verbindung mit einem auf die Bauform abgestimmten Gehäuse kompensieren Lager mit sphärischer Mantelfläche Fluchtungsfehler der Welle ➤ Abschnitt.

Die Spannlager sind bis auf wenige Ausnahmen nachschmierbar. Dazu haben sie zwei um 180° versetzte Schmierbohrungen in einer Ebene im Außenring.

Die Befestigung auf der Welle erfolgt durch Exzenterspannring, Gewindestifte im Innenring, Spannhülse, Mitnehmernut, Passung oder Profilbohrung ➤ Bild.

Zylindrische Mantelfläche für zylindrische Gehäusebohrung

Spannlager mit zylindrischer Mantelfläche sind einreihige, montagefertige Baueinheiten, bestehend aus massivem Außenring, ein- oder beidseitig verbreitertem Innenring, Käfigen aus Kunststoff und Dichtungen P oder R ➤ Tabelle. Lager mit beidseitig verbreitertem Innenring haben eine geringere Verkippung des Innenrings zur Folge und laufen dadurch ruhiger.

Die Spannlager sind befettet und können nicht nachgeschmiert werden.

Ihre Befestigung auf der Welle erfolgt durch Exzenterspannring, Passung oder Profilbohrung ➤ Link und ➤ Link.

Befestigung und Ausführung

Festlager

Zur Befestigung dienen Exzenterspannringe, Gewindestifte oder integrierte Spannhülsen ➤ Bild und ➤ Bild. Bestimmte Baureihen werden durch Passung auf der Welle fixiert. Die ein- oder beidseitige Verbreiterung des Innenrings wird als Lauffläche für die Dichtung genutzt und verhindert eine stärkere Verkippung des Innenrings.

Schwingungsgedämpfte Lager

Für Anwendungen, bei denen starke Schwingungen auftreten können, eignen sich zur Dämpfung Spannlager mit dickwandigem Gummidämmring ➤ Bild.

Loslager

Spannlager mit einer Mitnehmernut im Innenring sind Loslager, die bei niedrigen Drehzahlen und Belastungen zum Ausgleich von Längendehnungen der Welle eingesetzt werden ➤ Bild. Die Nut erlaubt eine einfache radiale Befestigung des Lagers auf der Welle.

|

Befestigungsarten der Spannlager

|

|

|

Ausführungsbeispiele der Spannlager

|

|

Spannlager mit Exzenterspannring

Diese „klassischen“ INA-Spannlager werden mit einem Spannring auf der Welle befestigt ➤ Bild. Sie sind besonders geeignet für Lagerungen mit gleichbleibender Drehrichtung; bei niedriger Drehzahl und Belastung auch für wechselnde Drehrichtung.

Der Spannring wird vorzugsweise in Drehrichtung verspannt und mit einem Gewindestift gesichert. Diese Verbindungsart schont die Welle und lässt sich leicht wieder lösen.

Abgedichtete Lager sind bis auf wenige Baureihen nachschmierbar.

Korrosionsschutz

Die Innenringe sind bis d = 60 mm, Spannringe generell Corrotect-beschichtet und so vor Passungsrost geschützt. Dies gilt nicht für die Baureihe RALE..-XL-NPP(-B).

|

Befestigung durch Exzenterspannring GE..-XL-KRR-B |

|

Spannlager mit Exzenterspannring und Nuten im Außenring

Die Grundform der Baureihe RAE..-XL-NPP-NR ist ein Spannlager mit Exzenterspannring und einseitig verbreitertem Innenring ➤ Bild. Der Außenring hat eine zylindrische Mantelfläche und zwei Nuten nach DIN 616 und ISO 464. Die Lager werden in zylindrische Bohrungen montiert und axial durch montagefreundliche Sprengringe fixiert. Ein Sprengring nach DIN 5417 ist bei der Lieferung montiert.

Die Spannlager sind befettet und nicht nachschmierbar.

Korrosionsschutz

Die Innenringe sind bis zu einem Bohrungsdurchmesser d = 60 mm Corrotect‑beschichtet und damit vor Passungsrost geschützt.

|

Spannlager mit zylindrischer Mantelfläche und zwei Nuten im Außenring RAE..-XL-NPP-NR |

|

Spannlager mit Gewindestiften im Innenring

Bei diesen Spannlagern wird der Innenring durch zwei um 120° versetzte Gewindestifte auf der Welle fixiert ➤ Bild. Diese Art eignet sich für Lagerungen mit gleichbleibender Drehrichtung, bei niedriger Drehzahl und Belastung auch für wechselnde Drehrichtung.

Die Gewindestifte sind selbsthemmend und haben ein Feingewinde mit Ringschneide zur sicheren Befestigung der Lager.

Die Lager sind, bis auf die Baureihe AY..-XL-NPP-B, nachschmierbar.

|

Befestigung durch Gewindestifte im Innenring GYE..-XL-KRR-B |

|

Spannlager mit Spannhülse

Bei dieser Baureihe wird der Innenring durch eine Spannhülse mit Nutmutter und Sicherungsblech auf der Welle befestigt ➤ Bild. Diese Spannlager eignen sich für Wellen bis Toleranzklasse h11 Ⓔ.

Die Lager sind nachschmierbar.

Für höhere Drehzahlen geeignet

Diese Art eignet sich für Lagerungen mit gleichbleibender oder wechselnder Drehrichtung und bei höheren Drehzahlen.

Spannhülse und Nutmutter verbinden den Lagerinnenring konzentrisch und kraftschlüssig mit der Welle. Dadurch sind Drehzahlen annähernd wie bei Rillenkugellagern möglich. Gleichzeitig ist bei diesen Lagern die Laufruhe höher als bei normalen Spannlagern. Spannhülse, Nutmutter und Sicherungsblech sind verzinkt.

Reversierbetrieb

Die Lager sind sehr gut für Reversierbetrieb geeignet. Durch die kraftschlüssige Verbindung entsteht keine Reibkorrosion zwischen Welle und Spannhülsenbohrung.

Austauschbarkeit

Durch die inkorporierte Spannhülse haben die Lager die gleichen radialen Abmessungen, bei geringfügig niedrigeren Tragzahlen, wie die Spannlager mit Exzenterspannring oder mit Gewindestiften im Innenring und sind mit diesen Lagern austauschbar.

|

Befestigung durch Spannhülse und Nutmutter GSH..-XL-2RSR-B |

|

Spannlager mit Mitnehmernut

Als Loslager bei niedrigen Drehzahlen einsetzbar

Spannlager mit Mitnehmernut im Innenring sind Loslager mit hochtemperaturbeständigen Eigenschaften ➤ Bild. Loslager werden bei niedrigen Drehzahlen und Belastungen zum Ausgleich von Längendehnungen der Welle eingesetzt.

Durch die Nut sind sie radial einfach zu befestigen. Die Verdrehsicherung kann durch einen Mitnehmerstift in der Welle oder durch einen Stellring mit Stift erfolgen. Die Loslager sind für gezogene Wellen der Toleranzklassen h5 Ⓔ bis h7 Ⓔ geeignet.

Die Lager sind nachschmierbar.

Korrosionsschutz

Die Innenringe sind bis zu einem Bohrungsdurchmesser d = 60 mm Corrotect‑beschichtet und damit vor Passungsrost geschützt.

|

Befestigung durch Mitnehmernut GLE..-XL-KRR-B |

|

Einstell-Rillenkugellager mit Bohrung für Passung

Einstell-Rillenkugellager gibt es mit zylindrischer Bohrung für Passungssitz ➤ Bild sowie mit geräumter Vierkant- und Sechskantbohrung ➤ Bild.

Die Außenring-Mantelfläche ist sphärisch.

Lager mit Passungssitz auf der Welle ermöglichen Drehzahlen wie Standardkugellager. Diese sind für Lagerungen mit wechselnder Drehrichtung geeignet und bieten eine gute Laufruhe.

|

Einstell-Rillenkugellager mit Passungssitz 2..-XL-NPP-B |

|

Für Einstell-Rillenkugellager mit Passungssitz gelten die Passungsangaben für Kugellager!

Rillenkugellager mit Bohrung für Passung

Diese Lager haben einen zylindrischen Außenring und werden in zylindrischen Bohrungen eingebaut ➤ Bild. Der Innenring ist beidseitig verbreitert und wird durch eine Passung auf der Welle befestigt. Durch den breiteren Innenring können zusätzliche axiale Distanzringe entfallen.

Der zentrische Sitz ermöglicht Drehzahlen wie von Standardkugellagern, die Belastung kann sowohl gleichbleibend als auch wechselnd sein. Gleichzeitig wird eine gute Laufruhe erreicht.

Die Toleranz der Innenringbohrung entspricht der Toleranzklasse Normal nach ISO 492.

Die nach außen abgewinkelten Blechscheiben bilden einen größeren Fettraum.

|

Rillenkugellager mit breitem Innenring und Bohrung für Passung 2..-XL-KRR 2..-XL-KRR-AH |

|

Einstell-Rillenkugellager mit profilierter Bohrung

Übertragung hoher Momente

Lager mit profilierter Bohrung werden eingesetzt, wenn Wellen sehr hohe Momente übertragen müssen und das nur mit Vierkant- oder Sechskantwellen möglich ist ➤ Bild. Die Verdrehsicherung erfolgt durch Formschluss.

Diese Lager haben einen sphärischen oder zylindrischen Außenring und einen beidseitig verbreiterten Innenring ➤ Bild und ➤ Bild. Es werden Wellen der Toleranzklasse h11 Ⓔ empfohlen.

Die Lager sind maximal befettet; einige Ausführungen mit sphärischer Mantelfläche sind auch nachschmierbar.

Korrosionsschutz

Die Lager sind Corrotect-beschichtet.

|

Einstell-Rillenkugellager mit profilierter Bohrung

VK..-KTT-B SK..-KRR-B |

|

|

Rillenkugellager mit breitem Innenring und profilierter Bohrung

SK..-KRR SK..-KTT |

|

Spannlager mit Gummidämmring

Spannlager mit Gummidämmring werden mit Exzenterspannring auf der Welle befestigt. Der Außenring ist mit einem dickwandigen NBR-Dämmring ummantelt ➤ Bild.

|

Spannlager mit Gummidämmring

Aufbau der Lagerbezeichnung ➤ Tabelle |

|

Gedämpfte Laufgeräusche

Der Dämmring nimmt Schwingungen und Stöße auf und dämpft dadurch Laufgeräusche.

Unterschiedliche Bauformen

Die Mantelfläche der Dämmringe ist sphärisch oder zylindrisch.

Für Walzenlagerungen gibt es eine Baureihe mit Anschlagschulter am Gummiring.

Lager mit Gummidämmring sind nicht nachschmierbar.

Rohr- und Gehäusedurchmesser für Spannlager mit Gummidämmring beachten:

- CRB: Rohrinnendurchmesser D –0,6 bis –1,6

- RABR, RCR, RCSM: Gehäusedurchmesser D –0,25 bis –0,35.

Korrosionsschutz

Innen- und Spannring sind Corrotect-beschichtet und dadurch vor Passungsrost geschützt. Dies gilt nicht für die Baureihen mit Spannlager RALE..-XL-NPP(-B).

Spannlager mit Einstellring aus Stahl

Diese Lager bauen auf Spannlagern mit Exzenterspannring oder Einstell-Rillenkugellagern auf, haben jedoch zusätzlich einen quergesprengten Außenring als Einstellring ➤ Bild. Sie werden in zylindrische Bohrungen montiert und kompensieren statische Fluchtungsfehler der Welle bis ±5°.

Bei der Baureihe PE wird der Innenring durch einen Spannring, bei der Baureihe BE durch Passung auf der Welle fixiert.

Spannlager mit Einstellring können nicht nachgeschmiert werden.

Für Blechkonstruktionen geeignet

Durch die Ringnuten im Außenring nach DIN 616 sind sie sehr gut für Blechkonstruktionen geeignet. Ihre axiale Befestigung erfolgt dort mit Sprengringen nach DIN 5417.

Für Einstellringe gelten die Passungstoleranzen der Rillenkugellager! Passung für Welle und Gehäuse so wählen, dass sich der Außenring des Spannlagers einstellen kann!

Korrosionsschutz

Der Einstellring ist Corrotect-beschichtet und dadurch vor Passungsrost geschützt. Bei der Baureihe PE..-XL sind zusätzlich auch der Innen- und Spannring beschichtet.

|

Spannlager mit Einstellring aus Stahl PE..-XL |

|

Korrosionsbeständige Lager in VA-Ausführung oder Corrotect‑beschichtet nach ISO

Die Spannlager SUB, SUC und SUG sowie die Spannlager mit dem Nachsetzzeichen FA125 sind für korrosionsbeständige Lagerungen ausgelegt. Sie eignen sich deshalb gleichermaßen gut für Anwendungen mit Feuchtigkeit, Schmutzwasser, Salzsprühnebel sowie bei Reinigungsmitteln. Ihre klassischen Einsatzgebiete sind der Agrar-, Bau- und Bergbaubereich, Förderanlagen, Textil-, Papier- und Holzbearbeitungsmaschinen sowie Maschinen für die Nahrungs- und Getränkeindustrie.

VA-Ausführung oder Corrotect‑beschichtet

Die Lager gibt es in VA‑Ausführung oder Corrotect-Dünnschicht-beschichtet ➤ Bild. Sie entsprechen in ihrem Aufbau einreihigen Rillenkugellagern 62, sind einbaufertig, besonders montagefreundlich und ermöglichen robuste, wirtschaftliche Lagerungen mit einer langen Gebrauchsdauer. Auf der Welle befestigt werden sie durch Gewindestifte im verlängerten Innenring oder mit einem Exzenterspannring.

Auf die Anwendung abgestimmte Dichtungen und Schmierfette sichern den Betrieb auch bei schwierigen Bedingungen.

|

Korrosionsbeständige Spannlager, Corrotect-beschichtet oder in VA-Ausführung

|

|

Spannlager in VA-Ausführung

Bei Spannlagern SUB, SUC und SUG bestehen Lagerringe, Exzenterspannring und Wälzkörper aus hochlegiertem, nichtrostendem Wälzlagerstahl mit erhöhtem Chrom-Molybdängehalt, Werkstoffnummer 1.4125.

Stahlblechkäfige aus rostfreiem Stahl, Werkstoffnummer 1.4301, halten und führen die Wälzkörper.

Befestigung mit VA‑Gewindestiften

Der Innenring wird durch zwei um 120° versetzte VA-Gewindestifte, Werkstoffnummer 1.4301, axial auf der Welle fixiert. Diese Befestigungsart eignet sich für Lagerungen mit gleichbleibender Drehrichtung, bei niedriger Drehzahl und Belastung auch für wechselnde Drehrichtung.

Die Gewindestifte sind selbsthemmend und haben ein Feingewinde mit Ringschneide zur sicheren Befestigung der Lager unter Berücksichtigung der angegebenen Anziehdrehmomente ➤ Tabelle.

Befestigung mit VA-Exzenterspannring

Die Lager werden mit einem VA-Spannring auf der Welle befestigt. Sie sind damit besonders geeignet für Lagerungen mit gleichbleibender Drehrichtung, bei niedriger Drehzahl und Belastung auch für wechselnde Drehrichtung.

Der Spannring wird vorzugsweise in Drehrichtung verspannt und muss mit dem Gewindestift gesichert werden. Diese Verbindungsart schont die Welle und lässt sich wieder leicht lösen.

Medienbeständigkeit

Insbesondere in der Nahrungsmittelindustrie ist die Beständigkeit des Werkstoffes hinsichtlich verschiedener Reinigungsmedien von zunehmender Bedeutung ➤ Tabelle.

Beständigkeit gegenüber Medien

|

Medium + beständig (+) mäßig beständig (–) kaum beständig – nicht beständig |

Konzentration |

X5CrNi18-10 |

440C |

||

|---|---|---|---|---|---|

|

% |

+20 °C |

+80 °C |

+20 °C |

+80 °C |

|

| Salzsäure HCl | |||||

| 0,1 |

+ |

+ |

‒ |

‒ |

|

| 1 |

(+) |

‒ |

‒ |

‒ |

|

| 18 |

‒ |

‒ |

‒ |

‒ |

|

| Flusssäure HF | |||||

|

1 |

‒ |

‒ |

‒ |

‒ |

|

|

5 |

-1) |

‒ |

-1) |

‒ |

|

| Schwefelsäure H2SO4 | |||||

| 1 |

+ |

‒ |

‒ |

‒ |

|

| 10 |

(+) |

‒ |

‒ |

‒ |

|

| 96 |

+ |

(+) |

‒ |

‒ |

|

| Schwefelige Säure H2SO3 | |||||

|

1 |

+ |

+ |

‒ |

‒ |

|

| Salpetersäure HNO3 | |||||

| 5 |

+ |

+ |

‒ |

‒ |

|

| 25 |

+ |

+ |

+ |

(+) |

|

| 65 |

+ |

+ |

+ |

(+) |

|

| Phosphorsäure H3PO4 | |||||

| 1 |

+ |

+ |

+ |

+ |

|

| 10 |

+ |

+ |

(+) |

+ |

|

| 85 |

+ |

+ |

+ |

‒ |

|

| Ameisensäure HCOOH | |||||

| 5 |

+ |

+ |

‒ |

‒ |

|

| 25 |

+ |

+ |

‒ |

‒ |

|

| Essigsäure CH3COOH | |||||

| 5 |

+ |

+ |

+ |

‒ |

|

| 25 |

+ |

+ |

+ |

‒ |

|

| Zitronensäure | |||||

|

5 |

+ |

+ |

+ |

+ |

|

|

25 |

+ |

+ |

‒ |

‒ |

|

| Chloressigsäure | |||||

|

5 |

+ |

+ |

(+) |

‒ |

|

| Natriumchlorid NaCl | |||||

|

10 |

+ |

+ |

(–) |

(–) |

|

| Meerwasser | |||||

|

4 |

+ |

+ |

(–) |

(–) |

|

| destilliertes Wasser | |||||

|

‒ |

+ |

+ |

+ |

+ |

|

| Ammoniumhydroxid NH4OH | |||||

|

1 |

+ |

+ |

+ |

+ |

|

|

10 |

+ |

+ |

+ |

+ |

|

| Kalilauge KOH | |||||

|

0,1 |

+ |

+ |

+ |

+ |

|

|

1 |

+ |

+ |

+ |

+ |

|

|

10 |

+ |

+ |

+ |

+ |

|

| Chlorbleichlauge | |||||

|

1 |

+1) |

+ |

2) |

(–) |

|

| Wasserstoffperoxid H2O2 | |||||

|

5 |

+ |

+ |

+ |

+ |

|

- Nicht geprüft. Einschätzung ergibt sich aus restlicher Versuchsreihe.

- Nicht geprüft. Einschätzung nicht möglich.

Spannlager mit Corrotect-Beschichtung

Die Spannlager GRAE..-XL-NPP-B-FA125 und GE..-XL-KRR-B-FA125 sind komplett Corrotect-Dünnschicht-beschichtet.

Kunststoffkäfige aus Polyamid PA66 halten und führen die Wälzkörper.

Korrosionsschutz- Schichtsystem Corrotect

Die Corrotect-Dünnschichttechnologie ist eine wirtschaftliche Alternative zu herkömmlich korrosionsgeschützten Spannlagern. Die Dicke der Schicht liegt zwischen 2 μm und 5 μm.

Vorteile der Corrotect-Dünnschichtbeschichtung sind:

- Allseitiger Korrosionsschutz auch an den gedrehten Oberflächen der Fasen und Radien

- Langfristig keine Unterrostung der Dichtungen

- Kleinere, bei der Anwendung beschädigte und dadurch blanke Stellen bleiben durch die kathodische Schutzwirkung korrosionsgeschützt

- Im Vergleich mit unbeschichteten Teilen ist die Gebrauchsdauer durch den Korrosionsschutz deutlich höher

- Baugleiche, unbeschichtete Lager und Gehäuse sind problemlos gegen beschichtete austauschbar

- Lager und Gehäuse aus rostfreiem Wälzlagerstahl sind häufig nicht mehr notwendig.

Für den direkten Kontakt mit Lebensmitteln ist die Corrotect-Dünnschichtbeschichtung nicht zugelassen.

Medienbeständigkeit

Die Beständigkeit der Corrotect-Dünnschichtbeschichtung gegenüber verschiedenen Medien ist zu beachten ➤ Tabelle.

Beständigkeit gegenüber Medien

|

Chemikalien |

Corrotect-Beschichtung |

|---|---|

|

neutrale, organische Flüssigkeiten |

beständig |

|

wässrige Salzlösungen im neutralen Bereich 6 ≦ pH ≧ 8 (Kochsalz NaCl, Seewasseranwendungen) |

bedingt beständig |

|

saure Flüssigkeiten (pH ≦ 6) |

unbeständig |

|

alkalische Flüssigkeiten (pH ≧ 8) |

unbeständig |

|

oxidierende Substanzen |

unbeständig |

- Gilt für Corrotect-Beschichtungen auf Basis von Zink und Zinklegierung.

Befestigung mit Spannring

Die Lager werden mit einem Spannring auf der Welle befestigt. Sie sind damit besonders geeignet für Lagerungen mit gleichbleibender Drehrichtung, bei niedriger Drehzahl und Belastung auch für wechselnde Drehrichtung.

Der Spannring wird vorzugsweise in Drehrichtung verspannt und muss mit dem Gewindestift gesichert werden. Diese Verbindungsart schont die Welle und lässt sich wieder leicht lösen.

Black Series nach JIS B 1558

FAG-Spannlager mit sphärischem Außenring basieren auf einreihigen Rillenkugellagern 62 und sind ausgelegt nach JIS B 1558. Die Black-Series-Spannlager gibt es mit zwei Befestigungsarten und einer Dichtungsart. Sie sind nachschmierbar und besonders montagefreundlich.

Die Spannlager sind vorbefettet und sind mittels zweier Schmierbohrungen im Außenring nachschmierbar.

Käfige aus Kunststoff

Die Lager haben Käfige aus Kunststoff ➤ Link und werden beidseitig mit einteiligen Dichtungen RSR mit anvulkanisierter Dichtlippe und einer vorgesetzten Schleuderscheibe abgedichtet.

Geräuscharm, geringes Reibmoment

Die gehonten Laufbahnen der Lagerringe zusammen mit der hohen Güteklasse der Kugeln sorgen für einen geräuscharmen Lauf und ein verringertes Reibmoment.

Basiskorrosionsschutz Durotect BS

Die Innen- und Außenringe sowie die Schleuderscheibe haben aufgrund der schwarzen Durotect BS-Beschichtung einen Basiskorrosionsschutz.

Spannhülsen sind Durotect BS-beschichtet oder phosphatiert.

Befestigung auf der Welle

Befestigung mit Gewindestiften

Bei den Spannlagern UC wird der Innenring durch zwei um 120° versetzte Gewindestifte auf der Welle fixiert ➤ Bild. Sie eignen sich für Lagerungen mit gleichbleibender Drehrichtung, bei niedriger Drehzahl und Belastung auch für wechselnde Drehrichtung.

Die Gewindestifte sind selbsthemmend und haben ein Feingewinde mit Ringschneide zur sicheren Befestigung der Lager. Zur besseren Unterscheidung sind die metrischen Gewindestifte mit Durotect BS beschichtet und die zölligen verzinkt.

|

Befestigung durch Gewindestifte im Innenring UC |

|

Befestigung mit Spannhülse

Bei den Spannlagern UK wird der Innenring durch eine konzentrische Spannhülse nach JIS B 1552 auf der Welle fixiert ➤ Bild. Die Rauheit der Spannhülse ist innen und außen Ra 2,5. Sie eignen sich für Lagerungen mit wechselnder Drehrichtung, auch bei hoher Drehzahl und Belastung.

|

Befestigung durch Spannhülse UK |

|

Baureihenvergleich der Spannlager

Mögliche Abmessungen und Merkmale der Standardlager sind in der folgenden Tabelle dargestellt ➤ Tabelle. Das korrosionsbeständige Spannlager-Programm und die Spannlager nach JIS (Black Series) sind extra zusammengefasst ➤ Tabelle.

Merkmale der Spannlager, Baureihenvergleich Standardlager

|

Baureihe |

Wellendurchmesser |

Befestigung |

Baureihe |

Zubehör |

Dichtung |

Kompensieren Fluchtungsfehler |

Lagerluft |

Käfig |

Baureihe |

Fett |

Nachschmier-bar |

Temperatur1) |

Bemerkung |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

mm |

inch |

°C |

|||||||||||||||

|

von |

bis |

von |

bis |

Group |

von |

bis |

|||||||||||

|

GE..-XL-KLL-B |

20 |

50 |

‒ |

‒ |

Exzenterspannring |

GE..-XL-KLL-B |

‒ |

L |

ja |

5 |

Stahl |

GE..-XL-KLL-B |

L069 |

ja |

–40 |

+180 |

‒ |

|

E..-XL-KLL |

20 |

50 |

‒ |

‒ |

Exzenterspannring |

E..-XL-KLL |

‒ |

L |

nein |

3 |

PA66 |

E..-XL-KLL |

GA13 |

nein |

–20 |

+100 |

‒ |

|

GRAE..-XL-NPP-B |

12 |

60 |

‒ |

‒ |

Exzenterspannring |

GRAE..-XL-NPP-B |

‒ |

P |

ja |

3 |

PA66 |

GRAE..-XL-NPP-B |

GA13 |

ja |

–20 |

+100 |

‒ |

|

GRA..-NPP-B-AS2/V |

‒ |

‒ |

5/8 | 1 15/16 | Exzenterspannring |

GRA..-NPP-B-AS2/V |

- |

P |

ja |

3 |

PA66 |

GRA..-NPP-B-AS2/V |

GA13 |

ja |

-20 |

+1002) |

|

|

RABRB..-XL-FA106 |

12 |

50 |

‒ |

‒ |

Exzenterspannring |

RABRB..-XL-FA106 |

Gummidämmring |

P |

ja |

3 |

PA66 |

RABRB..-XL-FA106 |

GA13 |

nein |

–20 |

+85 |

‒ |

|

RABRA..-XL-FA106 |

30 |

‒ |

‒ |

‒ |

Exzenterspannring |

RABRA..-XL-FA106 |

Gummidämmring | P | ja | 3 | PA66 |

RABRA..-XL-FA106 |

GA13 | nein | -20 | +85 |

leichte Reihe |

|

RAE..-XL-NPP-B |

12 |

50 |

‒ |

‒ |

Exzenterspannring |

RAE..-XL-NPP-B |

- |

P |

ja |

3 |

PA66 |

RAE..-XL-NPP-B |

GA13 |

nein |

–20 |

+1002) |

‒ |

|

RA..-NPP-B |

‒ |

‒ |

3/4 | 1 1/2 | Exzenterspannring |

RA..-NPP-B |

- |

P |

ja |

3 |

PA66 |

RA..-NPP-B |

GA13 |

nein |

-20 |

+1002) |

- |

|

RALE..-XL-NPP-B |

20 |

30 |

‒ |

‒ |

Exzenterspannring |

RALE..-XL-NPP-B |

- |

P |

ja |

3 |

PA66 |

RALE..-XL-NPP-B |

GA13 |

nein |

-20 |

+1002) |

leichte Reihe |

|

PE..-XL |

20 |

40 |

‒ |

‒ |

Exzenterspannring |

PE..-XL |

Einstellring |

P |

ja |

3 |

PA66 |

PE..-XL |

GA13 |

nein |

-20 |

+1002) |

Ringnuten im Einstellring |

|

RCSMB..-XL-FA106 |

15 |

25 |

‒ |

‒ |

Exzenterspannring |

RCSMB..-XL-FA106 |

Gummidämmring |

P |

nein |

3 |

PA66 |

RCSMB..-XL-FA106 |

GA13 |

nein |

–20 |

+85 |

‒ |

|

RCSMA..-XL-FA106 |

30 |

‒ |

‒ |

‒ |

Exzenterspannring |

RCSMA..-XL-FA106 |

Gummidämmring | P | nein | 3 | PA66 |

RCSMA..-XL-FA106 |

GA13 | nein | -20 | +85 |

leichte Reihe |

|

RCRA..-XL-FA106 |

20 |

‒ |

‒ |

‒ |

Exzenterspannring |

RCRA..-XL-FA106 |

Gummidämmring | P | nein | 3 | PA66 |

RCRA..-XL-FA106 |

GA13 | nein | -20 | +85 | leichte Reihe, Montagefase |

|

RCRB..-XL-FA106 |

20 |

‒ |

‒ |

‒ |

Exzenterspannring |

RCRB..-XL-FA106 |

Gummidämmring | P | nein | 3 | PA66 |

RCRB..-XL-FA106 |

GA13 | nein | -20 | +85 |

Montagefase |

|

CRB..-XL |

20 |

35 |

‒ |

‒ |

Exzenterspannring |

CRB..-XL |

Gummidämmring | P | nein | 3 | PA66 |

CRB..-XL |

GA13 | nein | -20 | +85 |

Anschlagschulter |

|

Baureihe |

Wellendurchmesser |

Befestigung |

Baureihe |

Zubehör |

Dichtung |

Kompensieren Fluchtungsfehler |

Lagerluft |

Käfig |

Baureihe |

Fett |

Nachschmierbar |

Temperatur1) |

Bemerkung |

||||

|

mm |

inch |

°C |

|||||||||||||||

|

von |

bis |

von |

bis |

Group |

von |

bis |

|||||||||||

|

RAE..-XL-NPP |

12 |

60 |

‒ |

‒ |

Exzenterspannring |

RAE..-XL-NPP |

‒ |

P |

nein |

3 |

PA66 |

RAE..-XL-NPP |

GA13 |

nein |

–20 |

+1002) |

‒ |

|

RALE..-XL-NPP |

20 |

30 |

‒ |

‒ |

Exzenterspannring |

RALE..-XL-NPP |

- |

P |

nein |

3 |

PA66 |

RALE..-XL-NPP |

GA13 |

nein |

–20 |

+1002) |

- |

|

RAE..-XL-NPP-NR |

20 |

40 |

‒ |

‒ |

Exzenterspannring |

RAE..-XL-NPP-NR |

- |

P |

nein |

3 |

PA66 |

RAE..-XL-NPP-NR |

GA13 |

nein |

–20 |

+1002) |

zwei Nuten, ein Sprengring |

|

RA..-NPP |

‒ |

‒ |

5/8 | 1 1/2 | Exzenterspannring |

RA..-NPP |

- |

P |

nein |

3 |

PA66 |

RA..-NPP |

GA13 |

nein |

–20 |

+1002) |

- |

|

RAL..-NPP |

‒ |

‒ |

3/4 |

‒ |

Exzenterspannring |

RAL..-NPP |

- |

P |

nein |

3 |

PA66 |

RAL..-NPP |

GA13 |

nein |

–20 |

+1002) |

- |

|

GE..-XL-KRR-B |

17 |

120 |

‒ |

‒ |

Exzenterspannring |

GE..-XL-KRR-B |

‒ |

R |

ja |

3 |

PA66 |

GE..-XL-KRR-B |

GA13 |

ja |

–20 |

+1002) |

‒ |

|

G..-KRR-B-AS2/V |

‒ |

‒ |

15/16 | 2 15/16 |

Exzenterspannring |

G..-KRR-B-AS2/V |

‒ |

R |

ja |

3 |

PA66 |

G..-KRR-B-AS2/V |

GA13 |

ja |

–20 |

+1002) |

‒ |

|

GE..-XL-KRR-B-2C |

25 |

40 |

‒ |

‒ |

Exzenterspannring |

GE..-XL-KRR-B-2C |

R |

ja |

3 |

PA66 |

GE..-XL-KRR-B-2C |

GA13 |

ja |

–20 |

+1002) |

Schleuderscheiben |

|

|

GNE..-XL-KRR-B |

30 |

100 |

‒ |

‒ |

Exzenterspannring |

GNE..-XL-KRR-B |

R |

ja |

3 |

PA66 |

GNE..-XL-KRR-B |

GA13 |

ja |

–20 |

+1002) |

schwere Reihe |

|

|

E..-XL-KRR-B |

25 |

40 |

‒ |

‒ |

Exzenterspannring |

E..-XL-KRR-B |

‒ |

R |

ja |

3 |

PA66 |

E..-XL-KRR-B |

GA13 |

nein |

–20 |

+1002) |

‒ |

|

NE..-XL-KRR-B |

50 |

‒ |

‒ |

‒ |

Exzenterspannring |

NE..-XL-KRR-B |

- |

R |

ja |

3 |

PA66 |

NE..-XL-KRR-B |

GA13 |

nein |

–20 |

+1002) |

schwere Reihe |

|

GE..-XL-KRR-B-FA101 |

20 |

75 |

‒ |

‒ |

Exzenterspannring |

GE..-XL-KRR-B-FA101 |

- |

R |

ja |

5 |

Stahl |

GE..-XL-KRR-B-FA101 |

L069 |

ja |

-40 |

+180 |

PTFE-Dichtlippe |

| GE..-XL-KRR-B-FA164 | 20 | 90 | - | - | Exzenterspannring | GE..-XL-KRR-B-FA164 | - | R | ja | 5 | Stahl | GE..-XL-KRR-B-FA164 | GA11 | ja | +150 | +250 |

PTFE-Dichtlippe |

|

E..-XL-KRR |

20 |

70 |

‒ |

‒ |

Exzenterspannring |

E..-XL-KRR |

‒ |

R |

nein |

3 |

PA66 |

E..-XL-KRR |

GA13 |

nein |

–20 |

+1002) |

‒ |

|

GE..-XL-KTT-B |

20 |

80 |

‒ |

‒ |

Exzenterspannring |

GE..-XL-KTT-B |

‒ |

T |

ja |

3 |

PA66 |

GE..-XL-KTT-B |

GA13 |

ja |

–20 |

+1002) |

‒ |

|

Baureihe |

Wellendurchmesser |

Befestigung |

Baureihe |

Zubehör |

Dichtung |

Kompensieren Fluchtungsfehler |

Lagerluft |

Käfig |

Baureihe |

Fett |

Nachschmier-bar |

Temperatur1) |

Bemerkung |

||||

|

mm |

inch |

°C |

|||||||||||||||

|

von |

bis |

von |

bis |

Group |

von |

bis |

|||||||||||

|

GAY..-XL-NPP-B |

12 |

60 |

‒ |

‒ |

Gewindestifte |

GAY..-XL-NPP-B |

‒ |

P |

ja |

3 |

PA66 |

GAY..-XL-NPP-B |

GA13 |

ja |

–20 |

+1002) |

‒ |

|

GAY..-NPP-B-AS2/V |

‒ |

‒ |

5/8 | 1 7/16 | Gewindestifte |

GAY..-NPP-B-AS2/V |

- |

P |

ja |

3 |

PA66 |

GAY..-NPP-B-AS2/V |

GA13 |

ja |

–20 |

+1002) |

- |

|

GYE..-XL-KRR-B |

12 |

90 |

‒ |

‒ |

Gewindestifte |

GYE..-XL-KRR-B |

- |

P |

ja |

3 |

PA66 |

GYE..-XL-KRR-B |

GA13 |

ja |

–20 |

+1002) |

- |

|

GY..-KRR-B-AS2/V |

‒ |

‒ |

1/2 | 2 15/16 | Gewindestifte |

GY..-KRR-B-AS2/V |

- |

P |

ja |

3 |

PA66 |

GY..-KRR-B-AS2/V |

GA13 |

ja |

–20 |

+1002) |

- |

|

AY..-XL-NPP-B |

12 |

30 |

‒ |

‒ |

Gewindestifte |

AY..-XL-NPP-B |

‒ |

P |

ja |

3 |

PA66 |

AY..-XL-NPP-B |

GA13 |

nein |

–20 |

+1002) |

‒ |

|

GAY..-XL-NPP-B-FA164 |

12 |

15 |

‒ |

‒ |

Gewindestifte |

GAY..-XL-NPP-B-FA164 |

‒ |

P |

ja |

5 |

Stahl |

GAY..-XL-NPP-B-FA164 |

GA11 |

ja |

+150 |

+250 |

PTFE-Dichtlippe |

|

GLE..-XL-KRR-B |

20 |

70 |

‒ |

‒ |

Mitnehmernut |

GLE..-XL-KRR-B |

‒ |

R |

ja |

5 |

Stahl |

GLE..-XL-KRR-B |

L069 |

ja |

–40 |

+180 |

PTFE-Dichtlippe |

|

BE..-XL |

20 |

40 |

‒ |

‒ |

Passung |

BE..-XL |

Einstellring |

P |

ja |

N |

PA66 |

BE..-XL |

GA13 |

nein |

–20 |

+1002) |

Ringnuten im Einstellring |

|

2..-XL-NPP-B |

12 |

50 |

‒ |

‒ |

Passung |

2..-XL-NPP-B |

‒ |

R |

ja |

N |

PA66 |

2..-XL-NPP-B |

GA13 |

nein |

–20 |

+1002) |

‒ |

|

2..-XL-KRR(-AH) |

13 |

60 |

‒ |

‒ |

Passung |

2..-XL-KRR(-AH) |

- |

R |

nein |

N |

PA66 |

2..-XL-KRR(-AH) |

GA13 |

nein |

–20 |

+1002) |

- |

|

SK(E)..-KRR-B |

16,1 |

38,1 |

‒ |

‒ |

Sechskantbohrung |

SK(E)..-KRR-B |

‒ |

R |

ja |

3 |

PA66 |

SK(E)..-KRR-B |

GA13 |

nein |

–20 |

+1002) |

korrosionsbeständig, |

|

SK..-KRR |

‒ |

‒ |

7/8 | 1 1/4 | Sechskantbohrung |

SK..-KRR |

- |

R |

nein |

3 |

PA66 |

SK..-KRR |

GA13 |

nein |

–20 |

+1002) |

korrosionsbeständig, |

|

SK..-KTT-B |

‒ |

‒ |

7/8 | 1 1/4 |

Sechskantbohrung |

SK..-KTT-B |

‒ |

T |

ja |

3 |

PA66 |

SK..-KTT-B |

L402 |

nein |

–20 |

+1002) |

korrosionsbeständig, |

|

SK..-KTT |

‒ |

‒ |

1 1/4 | 1 3/4 | Sechskantbohrung |

SK..-KTT |

- |

T |

nein |

3 |

PA66 |

SK..-KTT |

GA13 |

nein |

–20 |

+1002) |

korrosionsbeständig, |

|

GSH..-XL-2RSR-B3) |

20 |

50 |

‒ |

‒ |

Spannhülse |

GSH..-XL-2RSR-B |

‒ |

RSR |

ja |

4 |

PA66 |

GSH..-XL-2RSR-B |

GA13 |

ja |

–20 |

+1002) |

‒ |

|

GVK(E)..-KRR-B-AS2/V |

16,3 |

‒ |

‒ |

‒ |

Vierkantbohrung |

GVK(E)..-KRR-B-AS2/V |

‒ |

R |

ja |

3 |

PA66 |

GVK(E)..-KRR-B-AS2/V |

GA13 |

ja |

–20 |

+1002) |

korrosionsbeständig, |

|

VK(E)..-KTT-B |

25,4 |

38 |

1 |

‒ |

Vierkantbohrung |

VK(E)..-KTT-B |

- |

T |

ja | 3 | PA66 |

VK(E)..-KTT-B |

GA13 |

nein |

–20 |

+1002) |

korrosionsbeständig, |

|

GVK(E)..-KTT-B(-AS2/V) |

25,4 |

39,7 |

1 | 1 9/16 | Vierkantbohrung |

GVK(E)..-KTT-B(-AS2/V) |

- |

T |

ja | 3 | PA66 |

GVK(E)..-KTT-B(-AS2/V) |

GA13 |

ja |

–20 |

+1002) |

korrosionsbeständig, |

- Empfohlene Einsatztemperatur. Bei Temperaturen über +100 °C regelmäßig nachschmieren.

- Kurzzeitige Temperaturspitzen bis 120 °C möglich.

- Austauschbarkeit des Lagers beachten ➤ Link.

Merkmale der Spannlager, Baureihenvergleich, korrosionsbeständig und Black Series

|

Baureihe |

Wellendurchmesser |

Befestigung |

Dichtung |

Kompensieren Fluchtungsfehler |

Lagerluft |

Käfig |

Fett |

Nachschmierbar |

Temperatur |

Bemerkung |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

mm |

inch |

°C |

|||||||||||||

|

von |

bis |

von |

bis |

von |

bis |

||||||||||

|

Korrosionsbeständiges Programm |

|||||||||||||||

|

GRAE..-XL-NPP-B-FA125 |

20 |

60 |

‒ |

‒ |

Exzenterspannring |

P |

ja |

Group 3 |

PA66 |

GA47 |

ja |

–20 |

+1002) |

korrosionsbeständig, Corrotect-beschichtet |

|

|

GE..-XL-KRR-B-FA125 |

20 |

50 |

‒ |

‒ |

Exzenterspannring |

R |

ja |

Group 3 |

PA66 |

GA47 |

ja |

–20 |

+1002) |

korrosionsbeständig, Corrotect-beschichtet |

|

|

SUB |

20 |

50 |

‒ |

‒ |

Gewindestifte |

RSR |

ja |

Group 3 |

VA-Stahl |

FM222 |

ja |

–35 |

+100 |

korrosionsbeständig, VA‑Ausführung |

|

|

SUC |

12 |

50 |

‒ |

‒ |

Gewindestifte |

RSR |

ja |

Group 3 |

VA-Stahl |

FM222 |

ja |

–35 |

+100 |

korrosionsbeständig, VA‑Ausführung, |

|

|

SUG |

20 |

50 |

‒ |

‒ |

Exzenterspannring |

RSR |

ja |

Group 3 |

VA-Stahl |

FM222 |

ja |

–35 |

+100 |

korrosionsbeständig, VA‑Ausführung |

|

|

Black Series (Spannlager nach JIS) |

|||||||||||||||

| UC |

12 |

90 |

1/2 |

3 1/2 |

Gewindestifte |

RSR |

ja |

C3 |

PA66 |

GA13 |

ja |

–20 |

+1002) |

Black Series, Durotect BS‑beschichtet, Basis-Korrosionsschutz |

|

| UK |

20 |

80 |

‒ |

‒ |

Spannhülse |

RSR |

ja |

C4 |

PA66 |

GA13 |

ja |

–20 |

+1002) |

Black Series, Durotect BS‑beschichtet, Basis-Korrosionsschutz |

|

- Empfohlene Einsatztemperatur. Bei Temperaturen über +100 °C regelmäßig nachschmieren.

- Kurzzeitige Temperaturspitzen bis 120 °C möglich.

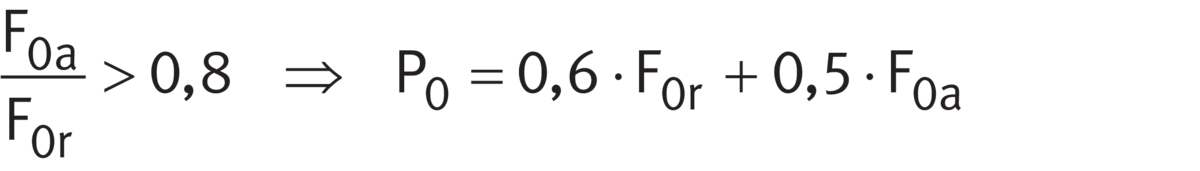

Belastbarkeit

Radiale Belastbarkeit

Für höhere radiale Belastungen geeignet

Die Kugeln berühren die Laufbahnen nur in einem Punkt. Bei rein radialer Belastung liegen die Kontaktpunkte von Wälzkörpern und Laufbahnen jeweils in der Laufbahnmitte. Damit geht die Verbindung der Kontaktpunkte durch die Radialebene; das heißt, die optimale Lastrichtung ist eine rein radiale Belastung ➤ Bild und ➤ Bild. Spannlager nehmen deshalb auch höhere radiale Belastungen auf.

Größere Kugelsätze erlauben höhere Belastungen

Die Belastbarkeit hängt von der Lagerreihe und der Größe des Kugelsatzes der Referenzlager ab. So ist die Rillenkugellager-Reihe 60 mit dem kleineren Lagerquerschnitt nicht so hoch belastbar wie die (auf den Bohrungsdurchmesser d bezogen) abmessungsgleiche Standard-Baureihe 62 mit einem größeren Kugelsatz. Die schwere Lagerbaureihe 63 mit dem größten Kugelsatz eignet sich für noch höhere Belastungen bei gleichem Bohrungsdurchmesser ➤ Bild.

|

Referenzlager, Querschnitts- und Tragfähigkeitsvergleich bei Lagern mit d = 40 mm Cr = Dynamische Tragzahl |

|

Axiale Belastbarkeit

Axial in beiden Richtungen belastbar

Aufgrund der tiefen Laufrillen in den Lagerringen und der engen Schmiegung zwischen den Laufrillen und Kugeln sind Spannlager axial in beiden Richtungen belastbar ➤ Bild und ➤ Bild. Die axiale Belastbarkeit hängt unter anderem von der Lagergröße, der inneren Konstruktion und dem Betriebsspiel ab. Eine zu hohe axiale Belastung kann jedoch das Laufgeräusch erhöhen und die Gebrauchsdauer der Lager erheblich verringern.

Bestehen Unsicherheiten bezüglich der axialen Belastbarkeit der Lager, bitte bei Schaeffler rückfragen.

Ausgleich von Winkelfehlern

Die Einheiten dürfen nicht zur Aufnahme von Schwenk- oder Taumelbewegungen eingesetzt werden ➤ Link.

Kompensation statischer Fluchtungsfehler

Lager mit sphärischer Mantelfläche des Lageraußenrings kompensieren in Gehäusen mit kugeliger Bohrung statische Fluchtungsfehler der Welle ➤ Bild, ➤ Bild und ➤ Bild.

Der Ausgleich von Fluchtungsfehlern muss innerhalb des zulässigen Winkels von ±5° für wartungsfreie oder ±2,5° für nachschmierbare Gehäuseeinheiten liegen. Voraussetzung ist, dass die Mittelachsen der Innenringe auf einer gemeinsamen Geraden liegen.

Für Einheiten mit Schmiernut im Gehäuse und Schmierbohrung im Spannlager gilt:

- Bis ±2,5° sind Einheiten nachschmierbar

- Zwischen ±2,5° und ±5° ist die Möglichkeit zur Nachschmierung von der jeweiligen Einheit abhängig. Hierzu bitte rückfragen

- Über ±5° ist keine Nachschmierung mehr möglich.

|

Kompensation statischer Fluchtungsfehler der Gehäuse ±5° bei wartungsfreien Lagern ±2,5° bei nachschmierbaren Lagern |

|

|

Kompensation statischer Fluchtungsfehler der Welle ±5° bei wartungsfreien Lagern ±2,5° bei nachschmierbaren Lagern |

|

|

Kompensation statischer Fluchtungsfehler der Welle ±5° bei wartungsfreien Lagern |

|

Spannlager für dauernde Pendelbewegung des Außenrings in der Gehäusebohrung nicht geeignet

Spannlager können nicht eingesetzt werden, wenn der Außenring in der Gehäusebohrung dauernd Pendelbewegungen ausführt. Das ist der Fall, wenn die Welle ein zu großes Untermaß aufweist oder die Mittelachsen der Innenringe von einer gemeinsamen Geraden so sehr abweichen, dass das im Lager vorhandene Kippspiel überschritten wird. In diesem Fall wird der Außenring über den Kugelsatz vom Innenring in die bei jeder Umdrehung des Lagers erfolgende Pendelbewegung mit einbezogen. Wie diese Situation sich darstellt, zeigen die Bilder an einer verbogenen Welle und einer Trommel mit parallelen, jedoch nicht fluchtenden Zapfen ➤ Bild und ➤ Bild. Diese Formfehler der Maschinenteile bewirken schon bei der Montage eine Verkippung des Lagers und bei der Rotation eine ständige Pendelbewegung des Außenrings.

|

Pendelbewegung der Außenringe bei verbogener Welle |

|

|

Pendelbewegung der Außenringe bei nicht fluchtendem Zapfen |

|

Eine unterdimensionierte Welle verursacht ständige Taumelbewegungen

Ebenfalls kritisch ist die Lagerung einer unterdimensionierten Welle ➤ Bild. Noch fluchtend im unbelasteten Zustand, biegt sie sich unter der Last durch, wie am Beispiel einer Umlenktrommel gezeigt. Dadurch führen die Lager eine ständige Taumelbewegung aus. Liegt in diesem Fall noch Umfangslast für den Außenring vor, wird das Ausschlagen der Gehäusebohrung beschleunigt (Verschleiß).

|

Pendelbewegung der Außenringe bei durchgebogener Welle |

|

Schmierung

Beidseitig abgedichtete Spannlager sind mit einem hochwertigen Lithiumseifenfett auf Mineralölbasis befettet, das über gute Korrosionsschutzeigenschaften verfügt ➤ Tabelle. Lager mit sphärischer Mantelfläche sind bis auf wenige Baureihen (wie AY..-XL-NPP-B) nachschmierbar.

Spannlager mit zylindrischer Mantelfläche sind maximal befettet. Die Fettfüllung ist dabei so bemessen, dass sie für die gesamte Lebensdauer des Lagers ausreicht. Dadurch sind diese Lager im Allgemeinen wartungsfrei. Spannlager können nach außen abgewinkelte Blechscheiben haben, die damit einen größeren Fettraum bilden. Nur wenige Ausführungen mit zylindrischer Mantelfläche sind zusätzlich nachschmierbar.

Spannlager mit Gummidämmring oder Einstellring sind nicht nachschmierbar.

Empfohlene Schmierfette für Spannlager

|

Kurzzeichen1) |

Klassifizierung |

Art des |

Empfohlenes |

|---|---|---|---|

|

GA13 |

Kugel- und Spannlagerfett Standard |

Lithiumseife Mineralöl |

Multi3 |

|

GA22 |

Leichtlauffett |

Lithiumseife Esteröl |

‒ |

|

L069 |

Spannlagerfett |

Polyharnstoff Esteröl |

‒ |

|

GA11 |

Medienbeständiges Wälzlagerfett |

PTFE Alkoxyfluorether |

Temp200 |

|

GA47 |

Medienbeständiges Wälzlagerfett |

Bariumkomplexseife Mineralöl |

‒ |

|

L178 |

Wälzlagerfett für hohe Drehzahlen |

Bariumkomplexseife PAO Öl |

‒ |

|

Fortsetzung ▼ |

|||

- GA steht für Grease Application Group, basierend auf Grease Spec 00.

Empfohlene Schmierfette für Spannlager

|

Kurzzeichen |

Gebrauchstemperaturbereich |

Obere Dauergrenztemperatur ϑGrenz,oben2) |

NLGI-Klasse |

Drehzahl-kennwert n · dM |

ISO-VG-Klasse (Grundöl) |

|||

|---|---|---|---|---|---|---|---|---|

|

°C |

°C |

min-1 · mm |

||||||

|

von |

bis |

von |

bis |

von |

bis |

|||

|

GA13 |

–30 | +120 | +75 | 3 |

‒ |

500 000 | 68 | 150 |

|

GA22 |

–50 | +120 | +70 | 2 |

‒ |

1 500 000 | 10 | 22 |

|

L069 |

–40 | +180 | +120 | 2 |

‒ |

700 000 | 68 | 220 |

|

GA11 |

–30 | +260 | +200 | 2 |

‒ |

300 000 | 460 | 680 |

|

GA47 |

–20 | +130 | +70 | 1 | 2 | 350 000 | 150 | 320 |

|

L178 |

–20 | +142 | +75 | 2 |

‒ |

800 000 | 22 | 46 |

|

Fortsetzung ▲ |

||||||||

- Die obere Dauer-grenztemperatur ϑGrenz,oben darf nicht überschritten werden, wenn eine temperaturbedingte Minderung der Fettgebrauchsdauer vermieden werden soll.

Verträglichkeit mit Kunststoffkäfigen

Werden Lager mit Kunststoffkäfig verwendet, ist sicherzustellen, dass beim Einsatz von Syntheseölen oder Schmierfetten auf Syntheseölbasis sowie bei Schmierstoffen mit einem hohen Anteil an EP‑Zusätzen die Verträglichkeit des Schmierstoffs mit dem Käfigmaterial gegeben ist.

Spannlager in VA-Ausführung

Als Erstbefettung wird ein Al-Komplexseifenfett mit Lebensmittelfreigabe nach NSF-H1 eingesetzt, das in vielen Fällen für die Gebrauchsdauer der Lager ausreicht. Zum Nachschmieren haben die Außenringe am Umfang Schmierbohrungen.

Black Series

Die Black-Series-Spannlager nach JIS sind mit einem Fett der Fettgruppe GA13 befettet ➤ Tabelle.

Abdichtung

Berührungsfreie oder berührende Dichtungen

Grundsätzlich unterscheidet man zwischen berührungsfreien und berührenden Dichtungen in der Anschlusskonstruktion und im Lager.

Die Abdichtung beeinflusst die Gebrauchsdauer einer Lagerung erheblich. Sie soll den Schmierstoff im Lager halten und verhindern, dass Verunreinigungen in das Lager gelangen.

Verunreinigungen können sich unterschiedlich auswirken:

- Eine große Zahl sehr kleiner, abrasiv wirkender Partikel erzeugt im Lager Verschleiß. Das größere Spiel oder das zunehmende Geräusch beendet die Gebrauchsdauer des Lagers

- Größere, überrollte harte Partikel vermindern die Ermüdungslebensdauer, weil sich bei hohen Lagerbelastungen an den Eindruckstellen Pittings bilden.

Bauformabhängige Dichtungen

Die unterschiedlichen Ausführungen der Dichtungen sind nachfolgend erläutert. Die bauformabhängigen Dichtungsformen, die in den einzelnen Spannlagern eingesetzt werden, sind in der Tabelle der Merkmale zusammengefasst ➤ Tabelle und ➤ Tabelle.

Übersicht Dichtungsformen

Dichtungen für Spannlager sind dreiteilig aufgebaut. Dieses Konzept bietet durch die fest eingerollte, innere Stahlblechscheibe einen optimalen Sitz im Lager und gleichzeitig eine konzentrische Einstellung der Dichtlippe zum Innenring. Die berührenden Dichtungen auf beiden Seiten des Lagers schützen vor Verschmutzung und dem Verlust von Schmierstoff.

Die Dichtungen für Spannlager sind in unterschiedlichen Ausführungen erhältlich ➤ Tabelle. Das angegebene Nachsetzzeichen wird im Bestellkurzzeichen angegeben und ist in der Tabelle der Nachsetzzeichen erläutert ➤ Abschnitt.

Dichtungsformen

|

P-Dichtung (NPP) |

|

|

Zwei verzinkte Stahlblechscheiben (oder in VA-Ausführung) mit dazwischenliegendem NBR-Teil, Dichtlippe axial vorgespannt. Zum Schutz der Dichtlippe vor mechanischer Beschädigung Eingesetzt in schmal bauenden Spannlagern |

|

R-Dichtung (KRR) |

|

|

Zwei verzinkte, nach außen abgewinkelte Stahlblechscheiben mit dazwischenliegendem NBR- oder PTFE-Teil und radial vorgespannter Dichtlippe. Besserer Schutz vor mechanischer Beschädigung. Größerer Fettraum durch die nach außen abgewinkelten Blechscheiben. Eingesetzt in Spannlagern mit beidseitig verbreitertem Innenring. |

|

R-Dichtung mit Schleuderscheibe (KRR-..-2C) |

|

|

Wie R-Dichtung, jedoch mit vorgesetzter, korrosionsgeschützter Schleuderscheibe. Zusätzliche Dichtwirkung ohne Einschränkung |

|

Fortsetzung ▼ |

|

Dichtungsformen

|

T-Dichtung (KTT) |

|

|

Zwei verzinkte Stahlblechscheiben mit dazwischenliegendem NBR-Teil und drei radial vorgespannten Dichtlippen gegen extrem starke Verschmutzung. Zum besseren Schutz der Dichtlippe vor mechanischer Beschädigung ist die äußere Blechscheibe nach außen abgewinkelt. Niedrigere Drehzahlen durch höhere Reibung. |

|

L-Dichtung (Labyrinthdichtung) (KLL) |

|

|

Zwei verzinkte Stahlblechscheiben im Außenring, dazwischen ein verzinkter Stahlblech-Winkelring auf den Innenring aufgepresst. Größerer Fettraum durch die nach außen abgewinkelten Blechscheiben. Eingesetzt in Lagern mit beidseitig verbreitertem Innenring. |

|

RSR-Dichtung (2RSR) |

|

|

Einteilige, verzinkte Stahlblechscheibe mit anvulkanisierter, radial vorgespannter Dichtlippe aus NBR. Eingesetzt in Spannlagern mit inkorporierter Spannhülse. |

|

RSR-Dichtung mit Schleuderscheibe |

|

|

Einteilige Stahlblechscheibe in VA-Ausführung mit anvulkanisierter und radial vorgespannter Dichtlippe aus NBR und vorgeschalteter Schleuderscheibe. Bei den Black Series ist die Schleuderscheibe Durotect BS-beschichtet. |

|

Dichtkassette mit Schleuderscheibe |

|

|

Aufbau wie normale Kassettendichtung, aber |

|

Kombinierte Dicht- und Schleuderscheibe mit Schutzscheibe |

|

|

Aufbau wie normale Dicht- und Schleuderscheibe, |

|

Fortsetzung ▲ |

|

BRS-Dichtungen

Auf Anfrage können Lager mit BRS-Dichtungen geliefert werden ➤ Bild.

Für höhere Drehzahlen geeignet

Die Reibung ist hier ebenso niedrig wie bei Lagern mit Deckscheiben. Gegenüber diesen haben sie jedoch den Vorteil, dass der äußere gummi-elastische Wulst in der Nut im Außenring gut abdichtet. Dies ist bei drehendem Außenring wichtig, da das Grundöl im Fett durch die Fliehkraft aus dem Seifengerüst herauszentrifugiert wird und bei Deckscheiben durch den undichten metallischen Sitz im Außenring austreten würde.

|

BRS-Dichtungen |

|

Berührungsfreie Dichtungen in der Anschlusskonstruktion

Bei berührungsfreien Dichtungen entsteht nur Schmierstoffreibung im Schmierspalt. Die Dichtungen verschleißen damit nicht und bleiben lange Zeit funktionsfähig. Da sie keine Wärme erzeugen, eignen sich berührungsfreie Dichtungen auch bei sehr hohen Drehzahlen.

Drehzahlen

Drehzahlgrenzen für Spannlager

Die Drehzahlgrenzen hängen ab von der Belastung, dem Spiel zwischen der Lagerbohrung und der Welle sowie von der Reibung der Dichtungen bei Lagern mit schleifender Dichtung.

Drehzahlgrenzen sind Richtwerte

Richtwerte für die zulässigen Drehzahlen können aus dem Diagramm abgelesen werden ➤ Bild.

Bei Belastungsverhältnissen Cr/P > 13 können die Drehzahlen erhöht werden. Bei Cr/P < 5 wird die Befestigung durch Passung bei einer Rauheit der Welle von Ra 0,3 empfohlen ➤ Link. Für schlupffreien Betrieb die radiale Mindestbelastung beachten ➤ Abschnitt.

|

Zulässige Drehzahlen für Spannlager n = zulässige Drehzahl d = Bohrungsdurchmesser Cr/P = Belastungsverhältnis h5, h6, h9 = Toleranz der Welle (es gilt die Hüllbedingung Ⓔ)

|

|

In den genannten Anwendungsfällen mit Belastungsverhältnissen Cr/P < 5 bitte rückfragen.

Beispiel zur Ermittlung der zulässigen Drehzahl

Gegeben:

| Toleranz der Welle | h6 Ⓔ |

| Spannlager | GRAE30-XL-NPP-B |

| Kugelsatz | 206 |

| Dynamische Tragzahl Cr | 20 700 N |

| Belastung P | 1 300 N |

| Abdichtung | Dichtungen P |

Gesucht:

| Belastungsverhältnis Cr/P = 20 700 N/1 300 N |

Cr/P > 13 |

| Zulässige Drehlzahl | n ≈ 4 300 min-1 ➤ Bild |

Geräusch

Schaeffler Geräuschindex

Der Schaeffler Geräuschindex (SGI) ist für diese Lagerart noch nicht verfügbar ➤ Link. Die Einführung und Aktualisierung der Daten für diese Baureihen erfolgt sukzessiv.

Temperaturbereich

Mögliche Betriebstemperaturen der Spannlager lassen sich nach der Käfigausführung und dem Werkstoff der Dichtlippen unterscheiden ➤ Tabelle.

Die Spannlager für hohen oder erweiterten Temperaturbereich haben die Nachsetzzeichen FA164 oder FA101 im Kurzzeichen ➤ Tabelle.

Zulässige Temperaturbereiche

|

Betriebstemperatur |

Spannlager |

|||||||

|---|---|---|---|---|---|---|---|---|

|

mit Polyamidkäfig PA66 |

mit Stahlblechkäfig |

mit Edelstahlkäfig |

||||||

|

mit NBR-Dichtlippe |

mit PTFE-Dichtlippe und Labyrinthdichtung |

mit NBR-Dichtlippe |

||||||

|

°C |

°C |

°C |

||||||

|

FA1013) |

FA1644) |

|||||||

|

von |

bis |

von |

bis |

von |

bis |

von |

bis |

|

|

|

–20 |

+1001)2) |

–40 |

+180 |

+150 |

+250 |

–35 |

+100 |

- Kurzzeitige Temperaturspitzen bis +120 °C möglich.

- Bei Spannlagern mit Gummidämmring reduziert sich die maximale Betriebstemperatur auf +85 °C.

- Hoch- und Tieftemperaturausführung (Nachsetzzeichen FA101) ➤ Abschnitt.

- Hochtemperaturausführung (Nachsetzzeichen FA164) ➤ Abschnitt.

Limitierende Größen

Die Betriebstemperatur der Lager ist begrenzt durch:

- die Maßstabilität der Lagerringe und Wälzkörper

- den Käfig

- den Schmierstoff

- die Dichtungen.

Sind Temperaturen zu erwarten, die außerhalb der angegebenen Werte liegen, bitte bei Schaeffler rückfragen.

Käfige

Wälzlagerkäfige werden in Blech- und Massivkäfige unterteilt.

Sowohl Blech- als auch Massivkäfige sind für Spannlager ausschließlich kugelgeführt.

Die wichtigsten Aufgaben des Käfigs sind:

- Die Wälzkörper voneinander zu trennen, um Reibung und Wärmeentwicklung möglichst gering zu halten

- Die Wälzkörper in gleichem Abstand voneinander zu halten, damit sich die Last gleichmäßig verteilt

- Wälzkörper in der unbelasteten Zone des Lagers zu führen.

Blechkäfige

Diese Käfige werden vorwiegend aus Stahl hergestellt ➤ Bild. Im Vergleich zu Massivkäfigen aus Metall haben sie ein geringeres Gewicht.

Weil ein Blechkäfig den Spalt zwischen Innenring und Außenring nur wenig ausfüllt, gelangt Schmierstoff leicht ins Lagerinnere und wird am Käfig gespeichert.

|

Spannlager mit Blechkäfigen

|

|

Massivkäfige aus Polyamid PA66

Massivkäfige aus Polyamid PA66 werden im Spritzgießverfahren hergestellt ➤ Bild und ➤ Bild. Damit können in der Regel Käfigformen verwirklicht werden, die besonders tragfähige Konstruktionen ermöglichen. Die Elastizität und das geringe Gewicht des Polyamids wirken sich günstig aus bei stoßartigen Lagerbeanspruchungen, hohen Beschleunigungen und Verzögerungen und bei Verkippungen der Lagerringe gegeneinander. Polyamidkäfige haben sehr gute Gleit- und Notlaufeigenschaften.

Käfige aus glasfaserverstärktem Polyamid PA66 eignen sich für Dauertemperaturen bis +120 °C. Aufgrund der eingesetzten Dichtung aus NBR reduziert sich die Dauertemperatur für das Spannlager ➤ Abschnitt.

|

Massivkäfig aus Polyamid bei Standardlagern

|

|

|

Massivkäfig aus Polyamid bei Black Series

|

|

Lagerluft

Die Unterscheidung der Spannlager nach ISO‑Programm und JIS‑Programm (Black Series) ist bei der radialen Lagerluft zu beachten.

Radiale Lagerluft der Spannlager

Die radiale Lagerluft ist bei den meisten Baureihen Group 3 nach ISO 5753-1 ➤ Tabelle und damit größer als bei normalen Rillenkugellagern ➤ Tabelle. Nach ISO 5753-1 ist die radiale Lagerluft in Gruppen unterteilt ➤ Bild.

Durch die größere Lagerluft werden Fluchtungsfehler und Wellendurchbiegungen besser aufgenommen.

|

Radiale Lagerluft |

|

Radiale Lagerluft der Spannlager (außer Black Series)

|

Bohrung |

Radiale Lagerluft |

||||||||

|---|---|---|---|---|---|---|---|---|---|

|

d mm |

Group N μm |

Group 3 μm |

Group 4 μm |

Group 5 μm |

|||||

|

über |

bis |

min. |

max. |

min. |

max. |

min. |

max. |

min. |

max. |

| 2,5 | 6 | 2 | 13 | 8 | 23 |

‒ |

‒ |

‒ |

‒ |

| 6 | 10 | 2 | 13 | 8 | 23 | 14 | 29 | 20 | 37 |

| 10 | 18 | 3 | 18 | 11 | 25 | 18 | 33 | 25 | 45 |

| 18 | 24 | 5 | 20 | 13 | 28 | 20 | 36 | 28 | 48 |

| 24 | 30 | 5 | 20 | 13 | 28 | 23 | 41 | 30 | 53 |

| 30 | 40 | 6 | 20 | 15 | 33 | 28 | 46 | 40 | 64 |

| 40 | 50 | 6 | 23 | 18 | 36 | 30 | 51 | 45 | 73 |

| 50 | 65 | 8 | 28 | 23 | 43 | 38 | 61 | 55 | 90 |

| 65 | 80 | 10 | 30 | 25 | 51 | 46 | 71 | 65 | 105 |

| 80 | 100 | 12 | 36 | 30 | 58 | 53 | 84 | 75 | 120 |

| 100 | 120 | 15 | 41 | 36 | 66 | 61 | 97 | 90 | 140 |

| 120 | 140 | 18 | 48 | 41 | 81 | 71 | 114 | 105 | 160 |

| 140 | 160 | 18 | 53 | 46 | 91 | 81 | 130 | 120 | 180 |

Radiale Lagerluft der Black Series (Spannlager nach JIS)

Die radiale Lagerluft entspricht nach JIS B 1520 C3 bei Spannlagern UC sowie C4 bei Spannlagern UK. Sie ist damit größer als bei normalen Rillenkugellagern ➤ Tabelle.

Durch die größere Lagerluft werden Fluchtungsfehler und Wellendurchbiegungen besser aufgenommen.

Radiale Lagerluft der Black Series

|

Bohrung |

Kugelsatz |

Außendurchmesser |

Radiale Lagerluft |

||||

|---|---|---|---|---|---|---|---|

|

d |

D |

C3 |

C4 |

||||

|

mm |

inch |

mm |

μm |

μm |

|||

|

min. |

max. |

min. |

max. |

||||

| 12 |

‒ |

204 | 47 | 13 | 28 | 20 | 36 |

| 12,7 | 1/2 | 204 | 47 | ||||

| 14,288 | 9/16 | 204 | 47 | ||||

| 15 |

‒ |

204 | 47 | ||||

| 15,875 | 5/8 | 204 | 47 | ||||

| 17 |

‒ |

204 | 47 | ||||

| 17,462 | 11/16 | 204 | 47 | ||||

| 19,05 | 3/4 | 204 | 47 | ||||

| 20 |

‒ |

204 | 47 | ||||

| 20,638 | 13/16 | 205 | 52 | 13 | 28 | 23 | 41 |

| 22,225 | 7/8 | 205 | 52 | ||||

| 23,812 | 15/16 | 205 | 52 | ||||

| 25 |

‒ |

205 | 52 | ||||

| 25,4 | 1 | 205 | 52 | ||||

| 26,988 | 1 1/16 | 206 | 62 | ||||

| 28,575 | 1 1/8 | 206 | 62 | ||||

| 30 |

‒ |

206 | 62 | ||||

| 30,162 | 1 3/16 | 206 | 62 | ||||

| 31,75 | 1 1/4 | 206 | 62 | ||||

| 31,75 | 1 1/4 | 207 | 72 | 15 | 33 | 28 | 46 |

| 33,338 | 1 5/16 | 207 | 72 | ||||

| 34,925 | 1 3/8 | 207 | 72 | ||||

| 35 |

‒ |

207 | 72 | ||||

| 36,512 | 1 7/16 | 207 | 72 | ||||

| 38,1 | 1 1/2 | 208 | 80 | ||||

| 39,688 | 1 9/16 | 208 | 80 | ||||

| 40 |

‒ |

208 | 80 | ||||

| 41,275 | 1 5/8 | 209 | 85 | 18 | 36 | 30 | 51 |

| 42,862 | 1 11/16 | 209 | 85 | ||||

| 44,45 | 1 3/4 | 209 | 85 | ||||

| 45 |

‒ |

209 | 85 | ||||

| 46,038 | 1 13/16 | 210 | 90 | ||||

| 47,625 | 1 7/8 | 210 | 90 | ||||

| 49,212 | 1 15/16 | 210 | 90 | ||||

| 50 |

‒ |

210 | 90 | ||||

| 50,8 | 2 | 210 | 90 | ||||

|

Fortsetzung ▼ |

|||||||

Radiale Lagerluft der Black Series

|

Bohrung |

Kugelsatz |

Außendurchmesser |

Radiale Lagerluft |

||||

|---|---|---|---|---|---|---|---|

|

d |

D |

C3 |

C4 |

||||

|

mm |

inch |

mm |

μm |

μm |

|||

|

min. |

max. |

min. |

max. |

||||

| 50,8 | 2 | 211 | 100 | 23 | 43 | 38 | 61 |

| 52,388 | 2 1/16 | 211 | 100 | ||||

| 53,975 | 2 1/8 | 211 | 100 | ||||

| 55 |

‒ |

211 | 100 | ||||

| 55,562 | 2 3/16 | 211 | 100 | ||||

| 57,15 | 2 1/4 | 212 | 110 | ||||

| 58,738 | 2 5/16 | 212 | 110 | ||||

| 60 |

‒ |

212 | 110 | ||||

| 60,325 | 2 3/8 | 212 | 110 | ||||

| 61,912 | 2 7/16 | 212 | 110 | ||||

| 63,5 | 2 1/2 | 213 | 120 | ||||

| 65 |

‒ |

213 | 120 | ||||

| 65,09 | 2 9/16 | 213 | 120 | ||||

| 66,675 | 2 5/8 | 214 | 125 | 25 | 51 | 46 | 71 |

| 68,262 | 2 11/16 | 214 | 125 | ||||

| 69,85 | 2 3/4 | 214 | 125 | ||||

| 70 |

‒ |

214 | 125 | ||||

| 71,438 | 2 13/16 | 215 | 130 | ||||

| 73,025 | 2 7/8 | 215 | 130 | ||||

| 74,612 | 2 15/16 | 215 | 130 | ||||

| 75 |

‒ |

215 | 130 | ||||

| 76,2 | 3 | 215 | 130 | ||||

| 77,787 | 3 1/16 | 216 | 140 | ||||

| 79,375 | 3 1/8 | 216 | 140 | ||||

| 80 |

‒ |

216 | 140 | ||||

| 80,962 | 3 3/16 | 216 | 140 | ||||

| 82,55 | 3 1/4 | 217 | 150 | 30 | 58 | 53 | 84 |

| 84,137 | 3 5/16 | 217 | 150 | ||||

| 85 |

‒ |

217 | 150 | ||||

| 87,312 | 3 7/16 | 217 | 150 | ||||

| 88,9 | 3 1/2 | 218 | 160 | ||||

| 90 |

‒ |

218 | 160 | ||||

| 93,662 | 3 11/16 | 219 | 170 | ||||

| 95 |

‒ |

219 | 170 | ||||

| 100 |

‒ |

220 | 180 | ||||

| 100,012 | 3 15/16 | 220 | 180 | ||||

| 101,6 | 4 | 220 | 180 | ||||

|

Fortsetzung ▲ |

|||||||

Abmessungen, Toleranzen

Die Hauptabmessungen der Standardlager und korrosionsbeständigen Spannlager entsprechen ISO 9628 und DIN 626-1.

Die Hauptabmessungen der Black Series entsprechen JIS B 1558.

Die Grenzmaße für Kantenabstände entsprechen DIN 620-6. Übersicht und Grenzwerte ➤ Link.

|

Symmetrischer Ringquerschnitt mit gleichen Kantenabständen bei beiden Ringen d = Innendurchmesser r1, r2 = Kantenabstände

|

|

Normaltoleranzen der Standardlager

Der Außendurchmesser der Lager entspricht der Toleranzklasse Normal nach ISO 492 ➤ Tabelle. Die Bohrung des Innenrings hat eine Plustoleranz zur einfacheren Montage des Lagers.

Toleranzen der Spannlager

|

Innenring |

Außenring |

||||||

|---|---|---|---|---|---|---|---|

|

Nennmaß Bohrung d |

Abweichung tΔdmp |

Nennmaß Außendurchmesser D |

Abweichung1)2) tΔDmp |

||||

|

mm |

μm |

mm |

μm |

||||

|

über |

bis |

L |

U |

über |

bis |

U |

L |

| 12 | 18 | 0 | +18 | 30 | 50 | 0 | –11 |

| 18 | 24 | 0 | +18 | 50 | 80 | 0 | –13 |

| 24 | 30 | 0 | +18 | 80 | 120 | 0 | –15 |

| 30 | 40 | 0 | +18 | 120 | 150 | 0 | –18 |

| 40 | 50 | 0 | +18 | 150 | 180 | 0 | –25 |

| 50 | 60 | 0 | +18 | 180 | 250 | 0 | –30 |

| 60 | 90 | 0 | +25 |

‒ |

‒ |

‒ |

‒ |

| 90 | 120 | 0 | +30 |

‒ |

‒ |

‒ |

‒ |

- Bei abgedichteten Lagern können der Größt- und Kleinstwert des Außendurchmessers vom Mittelwert etwa 0,03 mm abweichen.

- Toleranzen der Außendurchmesser auch für 2..-KRR und 2..-NPP-B gültig.

Toleranzsymbole ➤ Tabelle

U = Oberes Grenzabmaß

L = Unteres Grenzabmaß

Normaltoleranzen korrosionsbeständiger Spannlager

Der Außendurchmesser der Lager entspricht der Toleranzklasse Normal nach ISO 492 ➤ Tabelle und ➤ Tabelle. Die Bohrung des Innenrings hat eine Plustoleranz zur einfacheren Montage des Lagers.

Toleranzen der Spannlager, Corrotect‑beschichtet

|

Innenring |

Außenring |

||||||

|---|---|---|---|---|---|---|---|

|

Nennmaß Bohrung d |

Abweichung tΔdmp |

Nennmaß Außendurchmesser D |

Abweichung1) tΔDmp |

||||

|

mm |

μm |

mm |

μm |

||||

|

über |

bis |

L |

U |

über |

bis |

U |

L |

| 12 | 18 | 0 | +18 | 30 | 50 | 0 | –11 |

| 18 | 24 | 0 | +18 | 50 | 80 | 0 | –13 |

| 24 | 30 | 0 | +18 | 80 | 120 | 0 | –15 |

| 30 | 40 | 0 | +18 | 120 | 150 | 0 | –18 |

| 40 | 50 | 0 | +18 | 150 | 180 | 0 | –25 |

| 50 | 60 | 0 | +18 | 180 | 250 | 0 | –30 |

| 60 | 90 | 0 | +25 |

‒ |

‒ |

‒ |

‒ |

| 90 | 120 | 0 | +30 |

‒ |

‒ |

‒ |

‒ |

- Bei abgedichteten Lagern können der Größt- und Kleinstwert des Außendurchmessers vom Mittelwert etwa 0,03 mm abweichen.

Toleranzsymbole ➤ Tabelle

U = Oberes Grenzabmaß

L = Unteres Grenzabmaß

Toleranzen der Spannlager, VA‑Ausführung

|

Innenring |

Außenring |

||||||

|---|---|---|---|---|---|---|---|

|

Nennmaß Bohrung d |

Abweichung tΔdmp |

Nennmaß Außendurchmesser D |

Abweichung1) tΔDmp |

||||

|

mm |

μm |

mm |

μm |

||||

|

über |

bis |

L |

U |

über |

bis |

U |

L |

| 18 | 24 | 0 | +25 | 50 | 80 | 0 | –13 |

| 24 | 30 | 0 | +25 | 80 | 120 | 0 | –13 |

| 30 | 40 | 0 | +25 | 120 | 150 | 0 | –13 |

| 40 | 50 | 0 | +25 | 150 | 180 | 0 | –13 |

| 50 | 60 | 0 | +25 | 180 | 250 | 0 | –13 |

- Bei abgedichteten Lagern können der Größt- und Kleinstwert des Außendurchmessers vom Mittelwert etwa 0,03 mm abweichen.

Toleranzsymbole ➤ Tabelle

U = Oberes Grenzabmaß

L = Unteres Grenzabmaß

Normaltoleranzen der Black Series (Spannlager nach JIS)

Die Toleranzen der Außendurchmesser der Lager entsprechen den Toleranzen nach JIS B 1558 ➤ Tabelle. Die Bohrung des Innenrings hat eine Plustoleranz zur einfacheren Montage des Lagers.

Toleranzen des Innenrings, Black Series

|

Nennmaß |

Abweichung1) |

Breitenabweichung |

|||

|---|---|---|---|---|---|

|

d |

Δdmp |

ΔBs |

|||

|

mm |

μm |

μm |

|||

|

über |

bis |

min. |

max. |

min. |

max. |

| 10 | 18 | 0 | +15 | –120 | 0 |

| 18 | 31,75 | 0 | +18 | –120 | 0 |

| 31,75 | 50,8 | 0 | +21 | –120 | 0 |

| 50,8 | 80,962 | 0 | +24 | –150 | 0 |

| 80,962 | 120 | 0 | +28 | –200 | 0 |

- Entspricht dem arithmetischen Mittelwert aus dem größten und kleinsten erhaltenen Durchmesser (gemessen mit Zweipunktmessgerät).

Toleranzen des Außenrings, Black Series

|

Nennmaß |

Abweichung1) |

||

|---|---|---|---|

|

Dsp |

ΔDm |

||

|

mm |

μm |

||

|

über |

bis |

min. |

max. |

| 30 | 50 | –11 | 0 |

| 50 | 80 | –13 | 0 |

| 80 | 120 | –15 | 0 |

| 120 | 150 | –18 | 0 |

| 150 | 180 | –25 | 0 |

| 180 | 250 | –30 | 0 |

- Bei abgedichteten Lagern können der Größt- und Kleinstwert des Außendurchmessers vom Mittelwert etwa 0,03 mm abweichen.

Nachsetzzeichen

Das Nachsetzzeichen definiert spezielle Ausführungen und Merkmale und folgt nach dem Basiszeichen im Bestellkurzzeichen ➤ Tabelle und ➤ Tabelle.

Nachsetzzeichen und ihre Bedeutung

|

Nachsetzzeichen |

Beschreibung |

|

|---|---|---|

|

AS2/V |

Lageraußenring mit zwei Schmierbohrungen |

Standard |

|

B |

Lager mit sphärischer Mantelfläche des Außenringes |

Standard |

|

2C |

beidseitig mit Schleuderscheibe |

Standard |

|

FA |

Fertigungsvariante |

Standard |

|

FA101 |

Hoch- und Tieftemperaturausführung |

Standard |

|

FA106 |

Lager besonders geräuschgeprüft |

Standard |

|

FA107 |

Lager mit Schmierbohrungen |

Standard |

|

FA125 |

mit Corrotect-Beschichtung, korrosionsbeständig |

Standard |

|

FA164 |

Hochtemperaturausführung von +150 °C bis +250 °C |

Standard |

|

KRR |

beidseitig Lippendichtung (Dichtung R) |

Standard |

|

KLL |

beidseitig Labyrinthdichtung (Dichtung L) |

Standard |

|

KTT |

beidseitig 3-Lippendichtung (Dichtung T) |

Standard |

|

NPP |

beidseitig Lippendichtung (Dichtung P) |

Standard |

|

2RSR |

beidseitig Lippendichtung (anvulkanisiert) |

Standard |

|

AH |

abweichende Merkmale vom Original |

Standard |

|

NR |

Nut und Sprengring für Spannlager |

Standard |

|

OSE |

Lager ohne Spannelement (Exzenterspannring) |

Standard |

|

XL |

Lagerausführung in X-life-Qualität |

Standard |

Nachsetzzeichen und ihre Bedeutung, zusätzliche Angaben bei (Einstell-) Rillenkugellagern

|

Nachsetzzeichen |

Beschreibung |

|

|---|---|---|

|

L402/70 |

Fettcode nach Schaeffler-Standard, 70% Fettmenge |

auf Anfrage |

|

GA47/70 |

Fettgruppe, 70% Fettmenge |

auf Anfrage |

Aufbau der Lagerbezeichnung

Die Kurzzeichen bei Spannlagern mit verlängertem Innenring und (Einstell‑)Rillenkugellagern folgen nahezu dem gleichen Schema ➤ Tabelle, ➤ Bild und ➤ Bild. Spannlager mit Einstellring aus Stahl oder Gummidämmring weichen davon ab ➤ Link, ebenso wie Black Series und korrosionsbeständige Spannlager ➤ Link.

Basiszeichen und ihre Bedeutung bei Spannlagern mit verlängertem Innenring oder (Einstell-) Rillenkugellagern

|

Basiszeichen |

Bedeutung der Basiszeichen |

||

|---|---|---|---|

|

bei Angabe im Kurzzeichen |

ohne Angabe |

||

|

G |

nachschmierbar |

nicht nachschmierbar |

|

N |

schwere Lagerbaureihe (Lagerreihe 63) |

Standard-Lagerbaureihe (Lagerreihe 62) |

|

RA |

Innenringbefestigung |

Standard-Lagerbaureihe (Lagerreihe 62) |

|

AY |

Innenringbefestigung |

Standard-Lagerbaureihe (Lagerreihe 62) |

|

SH |

Innenringbefestigung mit Spannhülse (Sonderkugelsatz) |

Standard-Lagerbaureihe (Lagerreihe 62) |

|

|

RAL |

Innenringbefestigung |

Standard-Lagerbaureihe (Lagerreihe 62) |

+  |

VK |

Innenring mit Vierkantbohrung |

Innenring mit zylindrischer Bohrung |

+  |

SK |

Innenring mit Sechskantbohrung |

Innenring mit zylindrischer Bohrung |

|

Y |

Innenringbefestigung |

Innenringbefestigung mit Exzenterspannring, mit beidseitig verlängertem Innenring |

|

L |

Innenring mit Mitnehmernut (Loslager) |

Innenringbefestigung mit Exzenterspannring, mit beidseitig verlängertem Innenring |

|

|

E |

metrische Bohrung |

zöllige Bohrung |

|

1 |

zöllige Bohrung (nur bei beidseitig verlängertem Innenring) |

zöllige Bohrung |

|

|

50 |

Bohrungskennzahl; |

‒ |

|

0121) |

Bohrungskennzahl; |

‒ |

|

|

2042) |

Kugelsatzkennzahl (alleinige Angabe bei (Einstell-)Rillenkugellagern; Innenring mit Passung) |

‒ |

|

|

214 |

Kugelsatz 214 (zusätzliche Angabe) |

Standard |

- Dreistellige Angabe des Bohrungsdurchmesser. Die erste Stelle sind ganze Zoll, die beiden letzten Stellen werden in Sechzehntel angegeben, zum Beispiel 12/16.

- Die erste Zahl der Kugelsatzkennzahl entspricht der für Radial-Rillenkugellager genormten Baureihenbezeichnung ohne die führende 6, zum Beispiel Lagerbaureihe 62. Die weiteren Zahlen stehen für die Bohrungskennzahl, zum Beispiel 04. Für alle Wälzlager im Bereich von d = 20 mm bis d = 480 mm bildet man die Bohrungskennzahl, indem man das Maß der Lagerbohrung durch 5 dividiert.

|

Spannlager mit verlängertem Innenring:

Beispiel: |

|

|

(Einstell-) Rillenkugellager:

Beispiel: |

|

Spannlager mit Einstellring aus Stahl oder Gummidämmring

Spannlager mit Einstellring aus Stahl oder Gummidämmring folgen einem eigenen Kurzzeichenschema ➤ Tabelle und ➤ Tabelle.

Basiszeichen und ihre Bedeutung bei Spannlagern mit Einstellring aus Stahl

|

Basiszeichen |